"America's Cookie Mold Carvers"

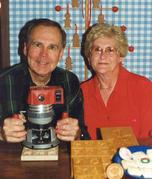

In 1970, Gene and June Wilson discovered wooden mold collections in US and European museums. Gene was smitten with the reverse carving - and soon turned his artistic talents to designing and carving wooden cookie molds. His first molds carved in 1970. He joined the Midwest Woodcarvers [Belleville Holzschnitzers] Club and began marketing his carvings.

June has helped over the past 50 years in testing cookie recipes and processing orders.

Gene has worked to perfect his technique of power tool engraving with a hand-held router. This innovative, self-taught type of freehand carving has allowed a vast variety of molds to be offered at affordable prices. Since no carving templates are used, each mold is an original carving with it's own "personality."

Allen Buchheit is Gene's nephew and apprentice. Allen will attempt to carry on this traditional carving of cookie stamps and molds for years to come.

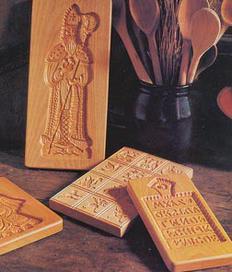

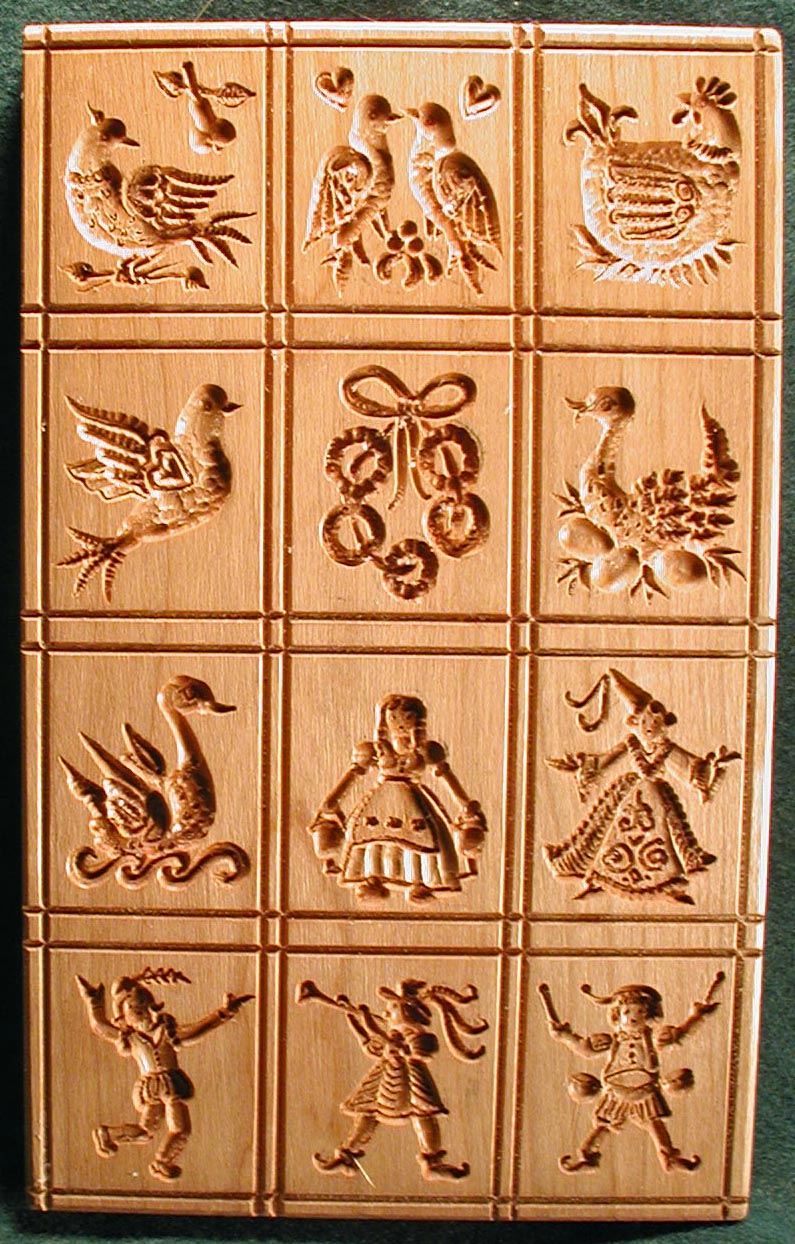

Over 100 designs of hand carved cookie molds are offered by mail order: springerle presses (molds), cookie stamps, deeply carved wooden cookie molds for shaping holiday picture cookies of German springerle ("springers") with or without anise. All molds are solid hardwood and ever so slightly different due being individually carved.

Modelschnitzer Gene Wilson has, for40+ years, carved gingerbread, Scottish shortbread, and Dutch speculaas molds. Each purchase of cookie mold carvings includes cookie recipes for use with wooden molds. HOBI Picture Cookie Molds

is that rare source of butter stamps, and gingerbread hornbook molds. Gene also handcrafts ABC hornbook replicas and has written some simple horn book histories.

Our solid, hardwood cookie molds are carved with hand-held power and hand tools - without the use of any carving templates or duplicatiing machinery.

AUTOBIOGRAPHY:

Farrell Eugene Wilson was born in Olney, Illinois where his parents ran Wilson Dairy Farm.

His great grandfather, S. C. "Sam" Wilson owned and operated "Our Daily

Bread" Flour Mill in Olney. Most of his family were farmers or teachers

in this part of southeastern Illinois . When Gene was one year old, his

father died and his mother sold the dairy farm and returned to teaching

to support her two young sons. The sons grew up in an environment of

teachers and grandparents. Woodworking as a hobby was a family tradition. Gene's artistic talent was inherited from his mother and shared by a number of his maternal relatives. His interest in art and science was inspired by his teachers and the abilities of

an older cousin, Bob Henry, killed in WWII.

Near the end of WWII, his mother remarried a farmer and major adjustments were required as Gene attended a one room school for three years. Farm life required Gene to develop a better knowledge of tools and gave him some valuable "hands on" mechanical experience. His participation in sports, and his work in Scouts, 4-H, and church youth groups helped him to develop some leadership experience that would better prepare him for a teaching career.

His high school classes (which included one year of shop and two years of art) were definitely not college preparatory! Planning on a career in printing Gene worked part-time in the print shop of a daily newspaper during his junior and senior years. "Morning farm chores, to work at the newspaper by 7 a.m., to school by 11 and home for chores by 4:30 p.m. was typical during those two years," he explains. Thus it was that he became accustomed to a busy schedule.

Upon graduation, he accepted a teaching scholarship and enrolled at SIU-C. Considering a major in art, he soon chose biology instead - as it left open an option to consider pre-med. Nearing graduation, he accepted a job teaching junior and senior high science. He and June, an elementary teacher, were married that same year. After three years of teaching, he received another scholarship and earned his Master's Degree in biology from Arizona State University. In the following decade, the Wilson family of four (one son, one daughter) settled in Belleville and spent a number of summers away from home as Gene enrolled in various graduate courses. Gene was a full-time biology professor with Belleville Area College until his retirement in 1990. He continued to teach some courses, part-time, until 1994.

Gene is a member of the Belleville's Midwest Woodcarvers Club which sponsors the huge Woodcarving Art Show at the Belle-Clair Exposition Hall the first weekend in November. The Wilsons have exhibited and sold their carvings at this show for over 40 years.

Gene's cookie mold carvings were chosen as one of the HOLIDAY crafts in Early American Life's 2002 Holiday Craft Directory

Publicity in Print

Newspaper and magazine articles:

Wood Carving Illustrated, "Edible Art" by Mark Weinstein, Holiday 2004, Pp. 44-47.

Taste of Home, "His Carved Molds Shape Unique Christmas Treats"

P. 58, October-November, 1998.

St. Louis Post Dispatch (Food Section), "Retired Professor Carves Out A New Career" by Cleora Hughes, June 26, 2000.

Naples Daily News (Food Section), "Cookies Fit For Molding (Tested Recipes) by Cleora Hughes, September 13, 2000.

Early American Homes Christmas Book, "Irresistible Specialty Items"

Pp. 49, 66; Christmas 2000.

The World & I, "Edible Art - German Springerle Cookies are a Christmas tradition for both the table and tree" by Sharon Hudgins, Pp. 130-137, December 2001

Better Homes and Gardens Christmas Cookies "Making Good Impressions," Pp. 80-81; by Peggy Rahn, December, 1996

3/1/07: "Nobody can believe you use a 7 lb. router to do such delicate carving. Everyone is amazed." Darlene H., NC

Hand Carved Picture-Cookie Molds

Our Carvers and Our Carvings ~ Frequently Asked Questions

"AMERICA'S COOKIE MOLD CARVER"

This page was last updated: July 20, 2021

HOBI Cookie Molds

PAGE

36

47

YEARS IN

BUSINESS

1974-2021

Q # 1. What are cookie molds and how are they carved?

Cookie molds are "dough shapers" used to produce fancy figure picture cookies.

Today, reasonably priced wooden molds for shaping cookie dough are difficult to find.

The antique ones are too expensive and rare. Most of the "tourist trade" wooden

molds produced today in Europe lack carving detail and artisitic appeal. Holzschnitzer

Gene Wilson of Illinois provides the artist's touch - and his own self taught technique

of hand-held, power tool carving - to transform random length and width hardwoods

(American cherry and beechwood) into attractive cookie and butter molds. His

reverse (intaglio) carvings are like those produced centuries ago in Europe and in

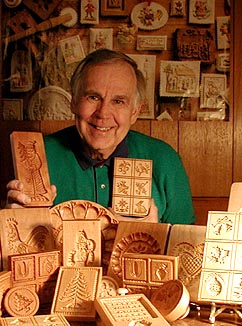

Colonial America. He carves and markets nearly one hundred different designs of

detailed cookie molds. Clean, sharp cuts result from his 40 years of experience, the

use of quality hard woods and sharp router bits. Most days of the year, Gene can be

found in the basement workshop of their comfortable colonial home carving molds

needed to fill hundreds of orders received each year.

"Carving wooden cookie molds is a dying European art," Gene explains, "an art that June and I are trying to keep alive." Ironically, orders for molds have been received from Europe. The Wilsons' last trips to Europe proved to be disappointing in regard to both the availability and quality of wooden molds. They feel that it is especially sad to see the art of carving and using traditional molds decline in the countries of their origin.

Q. # 2. What was Gene's Inspiration to Carve Molds?

Over four decades ago, during a visit to Colonial Williamsburg, Gene - and his wife June - fell in love with the antique molds used in the village bakery. Discovering "a vacuum of information," the Wilsons began their research of wooden molds. The concept of the mold's reverse images and the use of routers appealed to Gene as he had worked six years (part-time) during the 1950's in a daily news print shop. Gene, searching for new ways to combine his long time interests in art and woodworking,

began carving cookie mold plaques in 1972.

Without giving much thought to actually using the carved molds to shape cookie dough, he carved

them at the request of family and friends. Then, recalling the use of the molds seen in a bakery

at Colonial Williamsburg, the Wilsons experimented to find out how difficult it would be to shape

gingerbread cookies with wooden molds. They pressed dough into the designed cavities of his

molds. This led to improving the depth of carving, kitchen testing of recipes, and discovering a

few "secrets" that allow molds to more easily release the dough castings.

Familiar with the use of the router and the carving of redwood signs, Gene abandoned sign carving

in the 1970's as it seemed "too mechanical and lacking in artisitic expression." It was also about

that time that he gave up any hopes of moonlighting as a successful cartoonist. Thus, in the early

70's he redirected his artisitic and woodworking talents and took up the challenge of designing

and carving intricate molds that could be used to shape cookie dough. Soon the Wilsons were

searching for new ways to market unique cookie presses to bakers, collectors, and home decorators.

The developing craft market of the early 70's allowed Gene to carve out a niche for his new products. Today, his carvings are sought after as he is (to our knowlege) one of only three woodcarvers in the U. S. to produce a variety of handcarved molds for sale to the general public. Gene now carves over 1000 cookie stamps and molds per year. Carving on the backside of the mold, he initials and dates each piece - a practice much appreciated by cookie mold collectors and antique dealers.

Q. # 3 How are Gene's Molds Similar to Antique Wooden Molds?

The Wilsons have a collection of antique molds. Two groupings of antique molds are displayed on

the walls of their dining room: a group of Dutch molds and a group of 18th and 19th century

oriental molds. Their country kitchen displays June's antique butter mold collection, old

springerle presses, rollng pins, and several modern European molds.

Many visitors to Europe find themselves, sooner or later, in Innsbruck, Austria. In '97 the

Wilsons returned, for the second time, to view and photograph the antique in the

Tiroler Volkkunstmuseum (Tirolean Handicrafts Museum).

The Wilsons highly value three of their reference volumes on antique molds: (1) Edith Horandner's

richly illustrate MODEL Geschnitzte Formen fur Lebkuchen, Spekulatisus und Springerle, 220

pages, Callwey Verlag, Munchen , 1982; (2) J. J. Schilstra's richly illustrated Prenten in hout -

Speculaas, taai- en dragantvormen in Nederland, 330 pages, Lochem, 10985; and

(3) Paul E Kindig's illustrated Butter Prints and Molds, 248 pages, Schiffer Publishing, 1986.

Q. # 4. Why Use a Router to Carve Such Small Details?

Gene has stayed with the use of a full size electric router and his self-taught

type of carving despite the fact that the best known woodcarver in the U. S.

said that such a power tool could not be used for detailed carving of such molds.

Other carvers have examined his work and guessed that he used a pencil

shaped power tool - then find it difficult to believe that the majority of the

carving was done with a full size, seven pound router!

Router carving is noisy, dirty, and requires wearing a dust mask, - also eye and

ear protection. The upper body strength required causes fatigue and prohibits

long periods of continous carving. His control and ability to sequence the use of

different bits has improved each year so that he primarily uses two routers:

One router is 1 1/2 HP and the other 3 HP. Nevertheless, Gene prefers the

router for several reasons: (1) the router's weight provides stability that

minimizes the chance of ruining a nearly completed carving; (2) you can't make an

undercut which would keep the dough from releasing; (3) you can carve with

greater speed and therefore market original carvings at very reasonable prices.

Q. # 5. How Long Does It Take to Carve a Mold?

Gene finds this question a bit unfair and explains: "It took me thity years to learn, thirty

minutes to carve, thirty minutes to sand, shape, trace -- and ten minutes to apply finish...

in other words, it takes just a little over thirty years." For those wishing a direct answer,

the smallest of molds takes 10 minutes of carving time while the largest molds take well

over 4 hours. Power tools, used by most woodcarvers for some portion of their carving,

allow Gene to work faster than most carvers.

Gene often carves for two or three hours with the same carbide bit in the router, set to

the same depth. He might carve some small detail on 100 cookie stamps of ten different

designs. Gene finds that this efficient productivity sometimes causes boredom but allows

producing molds that are as affordable as they are unique. Since no carving templates are

used, each carving develops - as Gene likes to say - "its own personality."

Q. # 6. Does Carving the Same Designs Repeatedly Make it Easier?

Gene explains, "The longer that I carve the same design, the more detail I seem to add-- so, yes, it gets easier but it also gets better! "Customers who have collected my work over decades have noted that as I have increased the quantity of the molds I carve, the quality remains. Sadly, this is the exception to the rule for most production artists and craftsmen."

Q. # 7. Are The Designs Old or New?

Gene feels that the greatest challenge in carving is the designing of new wooden molds. Not every appealing design is suitable for a cookie stamp or mold. To ensure that the cookies bake evenly, the mold should be of a fairly uniform depth. It also must be of a fairly compact shape so that the cookie will release from the mold without breaking. Gene has carved over 200 different designs and has dozens of designs in his "idea file" that have never been carved.

A type of craft clay called 'super sculpey' is used as an aid in evaluating the details of a new mold design carved for the first time. Gene uses the clay for test impressions and makes adjustments in the depth and detail fo the carving process as he goes along. "After testing," he admits, "you sometimes have to re-work a design -- seems that you're always refining what you do."

A comparion of the molds he carves today with those he carved in the early '70s shows that a lot of refinement has occurred over the past decades. Obvious are improvements in the depth and detail of carving, in the finish, and in the wood quality. He now sands the wood smoother and slightly sands the edges of many molds to give them a softer and more finished look.

Gene observes that customers are more selective in what they purchase for gifts or to hang on their walls than in the early '70s. In general, "cute" is OUT, "unique" and "functional" are IN. Customers prefer a carving which is FUNCTIONAL even if it is purchased as a decorative accent and will never touch food!

Antique molds serve as a pattern for some of his work, but most of his designs are original. Original designs include most of his angels and santas, his Christmas springerle presses and ornaments, the Victorian springerle press, his Dutch and Alpine boys and girls, and many of the cookie stamp designs. "I enjoy new patterns and most of the time," Gene says, "what I like the best is what I've most recently carved for the first time."

Q. # 8. What Woods and Finishes are Used - and Why?

Beechwood and Cherry are the preferred woods for use with food as they have no odor or toxins. Gene likes beech because

of its lack of grain that detracts from the carved details. He likes the more expensive cherry when he can find it. American cherry is expensive and is increasingly used by the Wilsons. Such select hardwoods have to be purchased in the rough (random width and length) then planed and sawed to the desired dimensions. Both woods provide a density and durability

(resistance to marring) for producing heirloom molds and a resistance to being "burned" by router carving.

The salad bowl finish used by the Wilsons is a food-safe, non-toxic finish when cured. The product is manufactured by

General Finishes Corp., P. O. Box 51567, New Berlin, WI 53151. For the "B" finish, the Wilsons use two or three coats

to saturate the raw hardwood and produce a finish ideal for use in shaping cookie dough. The finish enhances the character

of the wood, stays clear or transparent, and has a satin finish. The salad bowl finish allows the mold to be used without any pre-conditioning and allows easy cleaning of the mold after use. The food safe salad bowl finish gives American cherry

wood a reddish brown finish that deepens in color and character with age.

A very few of Gene's customers order molds in raw wood (finish "A") because that is the way most of the European molds are sold. Gene and June find such molds difficult to use and strongly recommend the "B" finish for molds that are ready to use.

Since the Wilsons use two kinds of hardwoods they can not guarantee that two molds will have a perfectly matched finish.

Even if of the same species, no two pieces of wood are exactly the same in grain, density, and finished appearance.

If it is critical that molds have a perfectly matched finish, the customer is advised to order them at the same time

with a note that matching is very important.

Q. # 9. What Different Types of Wooden Molds does Gene Carve?

Cookie Stamps are carved in the greatest number - and are the easiest of the molds to use!

Springerle Presses are carved in large quantities. These molds have quaint designs that are pressed on dough of uniform thickness to make embossed picture-cookies.

Deep Cavity Molds are carved in smaller quantities. These molds are used to create cookie-art figures of European gingerbread, Dutch speculaas or Scottish shortbread.

Q. # 10. Why is Shaping Cookies with Wooden Molds a Tradition Worth Saving?

1. Molded picture cookies are a genuine art form, rich in cultural heritage.

2. Picture cookies have such festive and intricate designs that your adult guests often "taste"

such works of edible-art ONLY WITH THEIR EYES. only with their eyes!

3. By lacquering cookies them with transparent Krylon spray, you can render them non-edible but

create family heirloom Christmas tree ornaments.

4. A small tin of picture-cookies along with the cookie recipe makes a thoughtful gift - inclusion of the wooden

mold itself is a very special gift! A even better gift than this is going over to a friend's home

and showing them how to make picture cookies!

5. Having just the subtle evidence of having been used, the mold actually increases in aging and value.

Q. # 11. Are Recipes and Instructions Included?

Our booklet of recipes is included with each order. The Wilsons have discovered

a number of "secrets" that make the art of shaping edible picture cookies easier:

1. Dust the molds with powdered (confectioner's) sugar before impressing dough;

2. Chill the dough for 3+ hours or overnight before use; and

3. Press only portions of larger springerle presses so that the

impressions are a perfect reflection of the mold.

<<<< For those seeking a larger variety of recipes and techniques , we recommend

Anne L. Watson's BAKING WITH COOKIE MOLDS

Q. # 12. Are There Other Uses for these Wooden Molds?

Wooden molds have long been used for shaping things other than cookie dough such as butter, cream cheese, chocolate, clay, and wax. Recent craft ideas have included being used to create paper castings, salt dough ornaments, cinnamon ornaments, etc.

Hand Carved Picture-Cookie Molds

Our Carvers and Our Carvings ~ Frequently Asked Questions

Basic Facts about HOBI Cookie Molds and our 20 page website:

+ Basic products include [1] Cookie and Butter Stamps, [2] Springerle Molds,

[3] Deep Cavity Speculaas/Spekulatius and Gingerbread Molds, and [4] Hornbook

Replicas and History.

+ In business since 1974 by Gene Wilson. Current ownership by Allen and Karen Buchheit.

t+ Small business, no employees. Carving, web design, marketing and shipping by the owner.

+ At present, no wholesale of molds - nor carving of designs submitted by customers.

+ Sales limited to www.cookiemold.com and the annual Belleville Woodcarvers Art Show and Christkindlmarkt..

+ Molds of premium quality cherry and beech hardwoods, typically with a food-safe finish.

+ A booklet of kitchen-tested recipes & instructions is included with your order.and

a dozen recipes are included in this website for easy downloading!

Gene. age 84, has been an active member of Belleville Holzschnitzers and has displayed [and sold] his cookie mold carvings at the annual Belleville Art Show for over 40 years. He continues to carve an average of 20+ hours per week. He has always hoped [and now found] a family member desiring to continue his unique carving style. His nephew Allen is, under his guidance, is developing those skills. Your support of Allen's efforts will allow HOBI Cookie Molds to continue to offer customers a variety of reasonably priced original carvings.

C

O

M

M

E

N

T

2018 Sp;ring Issue of Woodcarving Illustrated features carvers of wooden cookie molds including

Gene and Allen

"MADE WITH LOVE"